Introduction

The fermenters are highly used for food processing, fermentation, waste treatment etc. This article is all about What is Fermenter and its types and uses. In general word, a fermentor is a type of closed vessel used for microorganisms’ growth under sterilized conditions for the production of metabolites.

An ideal fermentor should provide:

- Agitation – for mixing of the cells and medium.

- Aeration facilities – In the case of aerobic fermenters, an Oxygen supply is needed.

- Regation of factors like temperature, pH, pressure, nutrient feeding and liquid levelling.

- Sterilization and maintenance of sterility.

- Withdrawal of cells or medium in case of continuous culture process.

Modern fermenters are generally integrated with computers for efficient monitoring and data acquisition.

Types of fermenters

1. Batch Fermenters

Batch Fermenters – Batch fermenters are closed vessels where fermentation is carried out in a closed vessel.

The process where all the substrates are placed in the reactors at the start of the reaction, without any further outside interference is called Batch Fermentation.

-

Working Principle

It is a type of closed culture system.

The culture enters an exponential growth phase during which cells divide at a maximal rate and their generation time reaches the minimum.

The increasing population of bacterial cells enters into the stationary phase due to depletion of the nutrients. The stationary phase of the bacterial population culminates in the death phase when the viable bacterial cells begin to die. A characteristic growth curve is seen in a batch culture.

-

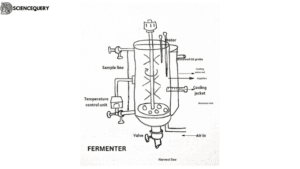

Diagram of a fermenter

Types of Phase

- Lag phase

It is the phase where the organisms are getting habituated to the surrounding medium and conditions.

- Log phase

This is the phase where generation time is calculated. It is the amount of time a bacteria needs to increase its population ratio. The better the conditions, the faster the growth rate shall be.

- Stationary phase

The stationary phase is due to growth limiting factors, mostly due to the depletion of nutrients or the formation of inhibitory products.

- Death phase

The cells begin to die due to a lack of nutrients and other conditions.

How is Batch Culture Operated?

- The first step to batch culture is sterilization. The sterile cultures are then inoculated with microbes at a suitable temperature.

The objective of sterilization is:

- To permit only the desired strain.

- To ensure the safety of the product.

- To avoid contamination of the environment.

- To prevent deterioration of the products.

- The medium is suitably stirred to keep the cells in suspension and to make the culture homogenous.

- Buffers are added to control the pH levels.

- Antifoaming agents are used to reduce the surface tension and destabilize the protein film. It helps in creating a hydrophobic bridge between surfaces.

- In the lag phase, very low growth can be seen in the beginning. This stage is considered the adaptive stage. The cell then enters the log phase once they are well adapted to the environmental conditions.

- The growth phase leads to the formation of primary metabolites like ethanol and organic acids.

- The stationary phase leads to the production of secondary metabolites. The death stage is achieved by the microorganisms due to the depletion of nutrients.

- The desired product is achieved at the last step.

Applications

- Production of Baker’s yeast from Saccharomyces cerevisiae species.

- Production of primary and secondary metabolites.

- SCPs are produced and used as a supplemental protein. They are produced from dried microbial cells like algae, yeast and fungi.

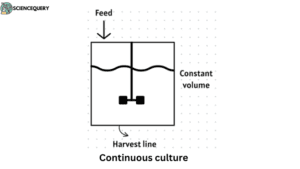

2. Continuous fermenters

Continuous fermentation is a type of continuous process where the nutrients are continually added and simultaneously removed at the same time.

Principle

It is a continuous culture process, carried out in an open system. The continuous cultures are generally carried out in small fermenters and maintained at lag and log phases only. Temperature and pH are controlled in this process.

Applications

- Citric acid is commercially produced by using this method.

- Production of primary metabolites including amino acids and organic acids.

- In the production of industrial alcohol.

How is continuous culture operated?

Continuous cultures are generally operated by two methods:

- Chemostat – The chemostat provides a uniform composition and a suitable environment for growth, ensuring continued cultivation. It allows a pure supply of batches and the removal of the results at a particular time.

- Turbidostat– As per the name, uniform turbidity is maintained in the culture vessels. The density of the cells is measured for the continued cultivation of batches.

Diagram

3. Fed-batch Fermenters

A fed-batch system is an advanced version of batch system culture. The nutrients are systematically added to the reactor. The nutrients are added systematically during the cultivation processes. After the products are ready, the whole process comes to a halt.

Principle

In this process, the substrates are introduced into the mixture at the start. The broth is usually not removed during the end of the process. As it remains semi-open, chances of contamination are high. The internal environment inside the fermenter stands constant and the volume of the nutrients is greater as compared to batch and continuous systems.

How are fed-batch cultures operated?

- Fed-batch culture is a fermentation method that involves providing the microorganism with nutrients at periodic intervals.

- The inoculum is added first, followed by the addition of desired nutrients at intervals. This helps in keeping an eye on the processing of yield and is an easy way to monitor cell growth.

- The volume of the nutrients increases, whereas pH and temperatures remain stable.

- The downstream processing technique is used for product cultivation.

Components and design of fermenters

The basic design of a fermenter

The basic fermenter should provide a controlled environment for optimum yield. It permits aseptic fermentation for many days to meet the requirements of contaminant regulations. Chemical-engineered methods are used for designing and operating bioreactors.

-

Vessel structure

Large cylindrical vessels of mild steel that permit sterilization with steam under pressure. Piping, joints and valves were designed to maintain aseptic conditions.

-

Agitation and mixing system

The medium must be suitably stirred to keep the cells in suspension and to make the culture homogeneous. The aim of stirring is to achieve good mixing without causing damage to the cells.

-

Aeration and oxygen supply

Aeration is done by perfusion step, where media is continuously taken from a culture. Its main function is to provide oxygen to the growing microorganisms.

-

pH and temperature control

The fermenter has an adequate provision for temperature control. Both microbial activity and agitation generate heat that requires cooling down.

In such cases, internal coils are used to circulate cold waters to remove excess heat.

Microbial cultivation & fermentation process

It includes

- Preparation of culture media.

- Inoculation of cultures to extract the desired product.

- Regulation of factors like temperature, pH, and oxygen levels.

- Harvesting high-quality products.

- Downstream processing is carried out.

Applications of fermenters

- In the production of organic solvents like acetone and butanol.

- In dairy industries, for the production of cheese, curd, buttermilk.

- In the fermentation of idli, dosa batter and bread.

- Wine production

- Antibiotics production including penicillin and streptomyces.

- Production of biosurfactants.

- Bioremediation for wastewater treatment.

Limitations

- There are chances of contamination as containers have semi-closure facilities.

- Possibilities of different variations with time.

- Cost efficiency is high.

- The Upscaling process is difficult to operate.

- Labour cost is high.

Advantages

- Simplified techniques and easier to use.

- Availability of media for the culture broth.

- Less energy and labour requirement for downstream harvesting.

- Better aeration facilities to improve cooling and support production rate.

- Productivity is high.

Safety and regulatory considerations

- A fermenter needs a controlled environment for optimum biomass production.

- The power consumption needs to be minimum and a dependable temperature control.

- A fermenter requires a containment regulation as it prevents the escape of viable cells.

- The production fermenters should have the capability to ensure scale-up.

- Fermenters must have a system for monitoring and regulating the pH of the fermentation broth.

Biohazards and contamination measures

Measures include

- Cleanliness and sterilized vessel– Fermenters need proper sterilization using hot steam and disinfectants, to prevent contamination.

- Handling materials – Gloves need to be used while working with fermenters to prevent industrial hazards.

- Raw materials storage – Raw materials need to be stored to prevent contamination from external factors like air-borne pollutants entering into fermenters.

- Regular monitoring of contamination, pH and temperature levels inside and outside the environment to ensure high yield products. Installation of sensors helps in detecting possible microbial growth that is necessary for the quality of the product.

Q&A

1. What do you mean by fermenter?

A fermentor is a type of fermentation vessel used for the production of various chemical and biological reactions.

2. What is a fermenter and what is it used for?

Fermenters are large vessels used for microbial culture processes to obtain biological products. They are closed containers with arrangements of oxygen supply, mixing, temperature regulation and management of pH factors.

3. How does a fermenter work?

Fermenters work on the principles of batch, fed-batch and continuous cultures.

The main difference between fermentation and fermenters

Fermentation is a process of breakdown of organic molecules into simpler molecules. It is strictly an anaerobic process. Microorganisms like yeast and bacteria play a vital role in the fermentation processes.

For example – a yoghurt starter is a mixed culture of Lactobacillus bulgaricus and Streptococcus thermophilus.

A fermenter is a device in which a substrate of low value is utilized by living cells or enzymes to generate a product of higher value. They are extensively used in food processing, fermentation and waste treatment.

The first fermenter vessel was used to produce acetone by Clostridium acetobutylicum, during the first world war.

Summary

- Now let us see in short what is fermenter and what are the uses.

- A fermenter is a closed vessel for metabolite production by the use of microorganisms.

- An ideal fermenter should have a mixer, fresh oxygen supplies, factors regulation such as temperature, pH and pressure

- The first fermenter vessel was used to produce acetone by Clostridium acetobutylicum, during the first world war.

- Fermenters work on the principles of batch, fed-batch and continuous cultures.

- Fermenters need proper sterilization using hot steam and disinfectants, to prevent contamination.

- Industrial-engineered methods are employed for the design and operation of bioreactors.

- Production of primary metabolites including amino acids and organic acids.

- In the production of industrial alcohol and acetone.

- A fermenter has a controlled environment for optimum biomass production.

- They have a system for monitoring and regulating the pH of the fermentation broth.

References

https://www.sciencedirect.com/science/article/pii/S1369703X02001328

https://www.sciencedirect.com/science/article/pii/S016816561830018X

https://www.cabdirect.org/cabdirect/abstract/19972400268

https://www.cetjournal.it/index.php/cet/article/view/3061